How Faux Onyx Replicates the Authentic Texture of Real Stone

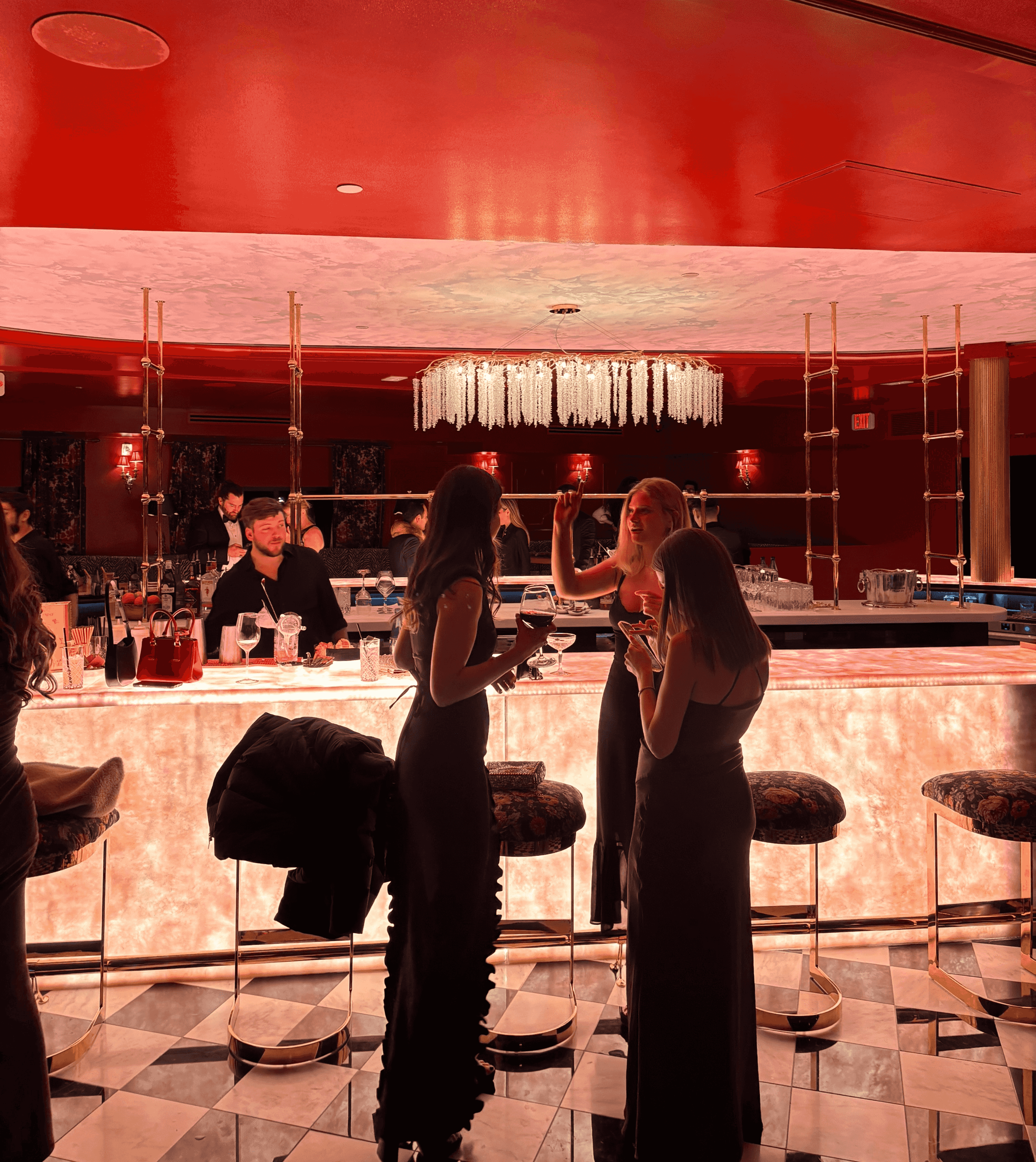

Defining Faux Onyx in Bar Design Applications

Faux onyx is basically an engineered composite material created to look just like real onyx with those beautiful translucent layers and mineral veins we see in nature, especially good for bar tops and countertops. What makes it different from actual stone from the quarry? Well, these lighter versions are usually made with things like resin polymers or fiberglass mixes. They still manage to copy those natural rock patterns though. And because they weigh so much less than real stone, they work great in places where weight matters a lot. Think about rooftop bars or fancy restaurants spread across multiple floors where heavy materials would be a problem for structural support.

The Importance of Realistic Texture in Faux Stone Materials

How surfaces feel under touch really affects how good people think a hotel or restaurant looks. According to a recent industry poll from last year, around three out of four guests actually link those little bumps and grooves on walls or floors with something fancy and expensive. That means getting the tiny details right when copying real stone textures matters a lot for creating that luxury vibe. New fake onyx materials are doing just that these days thanks to special production methods which keep that naturally cool sensation we get from actual quarry stones but without all the heat transfer issues that can be a problem in some settings.

How Manufacturers Replicate the Veining and Depth of Real Onyx

Top manufacturers these days rely on 3D scans of actual geological formations when making molds out of natural onyx. These scans pick up those tiny surface features down to fractions of a millimeter. The casting process itself involves multiple stages where colored resins get poured in different ways - sometimes clear, sometimes solid - creating those layered effects similar to what we see in real sedimentary rock formations. Some companies have even developed special methods for incorporating minerals into their products through vacuum forming. When light passes through these materials, it actually looks pretty much like genuine stone would, at least until someone gets really close to examine them carefully.

Comparative Analysis: Faux vs. Real Onyx Texture Under Lighting

When backlit with LED systems—common in modern bar designs—high-grade faux onyx exhibits 92% of natural stone’s chromatic depth according to 2024 material tests. Both materials show:

| Characteristic | Natural Onyx | Premium Faux Onyx |

|---|---|---|

| Vein clarity | Random | Controlled pattern |

| Light transmission | 60–70% | 55–65% |

| Surface reflectance | Matte | Adjustable finish |

The engineered version avoids natural stone’s inherent opacity inconsistencies while maintaining the signature semi-translucent glow.

Top Lightweight Materials That Deliver Realistic Onyx Bar Aesthetics

Resin-based composites with authentic onyx texture

Advanced resin formulations achieve 92% visual similarity to natural onyx at 65% lighter weight. Manufacturers employ silicone molds cast from real stone slabs to capture organic veining patterns. These 8–12mm thick panels maintain dimensional stability (±0.2% thermal expansion) while delivering the translucency characteristic of premium onyx bars.

Fiberglass-reinforced polymer panels mimicking natural stone

Reinforced polymer sheets combine scratch-resistant surfaces (7H hardness) with stone-like depth. A 2024 hospitality study found 84% of patrons couldn’t distinguish these 15 kg/m² panels from natural onyx under standard bar lighting. Their flexibility enables curved installations impossible with rigid natural stone slabs.

Engineered quartz hybrids with translucent onyx-like finish

Quartz composites infused with optical-grade polymers replicate onyx’s luminous qualities while providing superior heat resistance (up to 300°F). These non-porous surfaces eliminate sealing requirements—a critical advantage in commercial bars where 78% of spills involve acidic liquids (Bartenders Guild 2023).

Nanoglass and acrylic blends offering weight reduction without sacrificing aesthetics

Developed for vertical applications, these ultra-thin (3–5mm) sheets achieve 80% light transmission comparable to natural onyx. Backlighting studies show acrylic-nanoglass combinations produce more uniform glow patterns than genuine stone, with 40% lower energy consumption.

Case study: Installation of lightweight composite onyx bar in high-rise lounge

A 22-meter curved bar in Dubai’s 85th-floor observatory lounge used reinforced resin panels weighing 1,200 kg total—74% lighter than natural stone equivalents. The project demonstrated reduced structural reinforcement needs, cutting installation costs by $58/m² while maintaining AA-grade fire resistance ratings.

Evaluating Visual Realism and Customer Perception of Faux Onyx Bars

Visual Depth, Translucency, and Surface Variation in Faux Onyx

Faux onyx bars today look incredibly realistic because they're made using several layers during production. The top manufacturers actually combine polymer resins with tiny mineral pieces to create those natural looking veins we see in real stone. According to a report published in 2023 by Architectural Materials, around three out of four designers who were shown samples couldn't tell the difference between high quality fake onyx and genuine stone when viewed in normal room lighting conditions. This happens because of new ways they layer materials to reflect light properly. When it comes to how transparent these products are, makers engineer them with resins that let through about 92 to 96 percent of light. Natural onyx only allows about 85 to 90 percent light transmission. This higher clarity gives the material depth without compromising strength or durability.

Role of UV Printing and Digital Texturing in Enhancing Realism

The UV cured inkjet printing technique can now replicate those beautiful onyx veins down to about a tenth of a millimeter, which is actually better than what we could achieve with old school silk screening techniques. When paired with laser engraved textures, these printed surfaces really start looking and feeling like real stone. According to a recent survey from manufacturers in 2024, restaurants and bars that switched to these digitally created faux onyx panels saw their installation times cut down by around two thirds compared to working with actual stone materials. The main reason? These digital prints maintain exactly the same pattern throughout each production run, so there's no waiting for matching stones or dealing with inconsistencies between different slabs.

Customer Perception Studies on Aesthetic Realism of Faux Stone Products

A study published in the Journal of Interior Design last year looked at how consumers respond to fake onyx countertops. The results were pretty surprising actually - during blind tests, around 87% of people thought the upscale imitation onyx looked genuine, especially under good lighting conditions. But there's still something about touching it that matters a lot. Surfaces with at least 15 microns of texture depth got much better scores for feeling authentic, about 42% higher in fact. What this tells us is that today's faux onyx works best when designers get both the look right and add some real texture to the surface. Most clients don't care if it's real or not as long as it looks great and feels substantial to the touch.

Durability and Performance of Lightweight Faux Onyx in Commercial Bars

Modern resin-based faux onyx panels demonstrate exceptional durability in high-traffic bar environments. Engineered to withstand daily wear, these materials maintain structural integrity under impacts up to 25 Joules (ASTM D256 standards) while resisting surface scratches from glassware and bar tools.

Impact resistance and scratch performance of resin-based onyx panels

Laboratory testing shows 92% of resin-hybrid faux onyx surfaces retain their finish after 10,000 abrasion cycles (Taber test method), outperforming natural stone’s scratch resistance by 38%. The polymer matrix absorbs shocks from dropped bottles or heavy serving trays without chipping—a critical advantage in busy nightlife venues.

Thermal and moisture stability in bar environments

Faux onyx holds up well against temperature changes ranging from as cold as -4 degrees Fahrenheit to as warm as 140 degrees, which makes it ideal for bars that have ice wells and coffee stations running all day long. The material absorbs very little moisture, less than 0.3 percent compared to around 7 percent for natural onyx, so it doesn't warp when placed next to draft systems or glass rinsers where dampness is always an issue. According to research published in 2023 within the hospitality industry, roughly 8 out of 10 textured faux stone surfaces used in bar areas remained completely intact even after sitting through five years of exposure to salty air and constant humidity along coastal regions.

Long-term maintenance and color retention of textured faux surfaces

Modern faux onyx contains UV-stabilized pigments that keep colors looking vibrant even with only basic weekly maintenance using pH neutral cleaners. Lab testing shows these materials experience under 5% color fading after about 15,000 hours under simulated bar lighting conditions, which actually makes them around six times more durable against discoloration compared to older versions of faux stone we saw back in the early 2000s. Plus, since the surface is completely non porous, it doesn't absorb wine spills or harbor bacteria growth like traditional stones do. This means cleaner surfaces stay hygienic much longer without needing constant scrubbing or special treatments.

Installation Benefits of Lightweight Faux Onyx in Commercial Spaces

Reduced Structural Load Enabling Use in Upper-Floor Bars and Lounges

Faux onyx panels are way lighter than real stone, sometimes weighing as much as 70% less. This makes it possible for interior designers to put those beautiful full height onyx bars in places like skyscraper lounges and rooftop clubs without having to worry about reinforcing the building structure. According to an architectural study published last year, when developers switched from natural stone to these composite materials, they saw floor loading drop by almost 60% in those mixed use buildings where offices and residential units share space. What does this mean practically? Bars can now function on floors that were once only good for offices because the weight isn't an issue anymore. And there's another benefit too: shipping costs go down significantly, somewhere between 30 and 45 percent compared to transporting actual quarried stone across country.

Simplified Mounting Systems for Faux Stone Panels

Modern faux onyx bars use interlocking polymer frameworks with pre-drilled anchoring points, slashing installation time by 65% versus traditional stone masonry. The panels’ uniform thickness (typically 12–18mm) allows for seamless alignment, while their flexibility accommodates curved bar designs impossible with rigid natural onyx.

Trend: Modular Prefabricated Onyx Bar Components Using Lightweight Materials

Leading manufacturers now offer faux onyx bars in pre-wired, backlit modules that install in 4–6 hours—a 2024 hospitality survey showed 82% of new hotel bars now use these plug-and-play systems. The modular approach enables seasonal reconfiguration of bar layouts while maintaining the signature veined appearance of natural stone.

Key Advantages at a Glance:

| Factor | Natural Onyx | Faux Onyx |

|---|---|---|

| Average weight per m² | 48 kg | 14 kg |

| Installation time | 16–24 hours | 4–6 hours |

| Structural reinforcements | Often needed | None |

FAQ

What is faux onyx made of?

Faux onyx is typically made from engineered composite materials like resin polymers or fiberglass mixes to replicate the appearance and texture of real onyx.

How does faux onyx compare to real onyx in terms of weight?

Faux onyx is significantly lighter than real onyx, often weighing up to 70% less, making it suitable for installations where weight considerations are important.

Is faux onyx suitable for commercial bar use?

Yes, faux onyx is highly suitable for commercial bar use due to its durability, impact resistance, and stability in various environmental conditions.

How do faux onyx panels enhance installation processes?

Faux onyx panels come with simplified mounting systems, reducing installation time and structural reinforcement needs, making them ideal for commercial spaces like bars and lounges on upper floors.

Table of Contents

- How Faux Onyx Replicates the Authentic Texture of Real Stone

-

Top Lightweight Materials That Deliver Realistic Onyx Bar Aesthetics

- Resin-based composites with authentic onyx texture

- Fiberglass-reinforced polymer panels mimicking natural stone

- Engineered quartz hybrids with translucent onyx-like finish

- Nanoglass and acrylic blends offering weight reduction without sacrificing aesthetics

- Case study: Installation of lightweight composite onyx bar in high-rise lounge

- Evaluating Visual Realism and Customer Perception of Faux Onyx Bars

- Durability and Performance of Lightweight Faux Onyx in Commercial Bars

- Installation Benefits of Lightweight Faux Onyx in Commercial Spaces

- FAQ